But what do you suggest here? What do you mean by footprint - just give it more space on the PCB? Or make some of the copper larger and via stitch that too? 90 degree traces are bad? Should I break those down to 45? Does it really matter for logic traces? 2A is a little bit too much for 2.54mm headers? I don't understand.

#Diptrace tented vias driver#

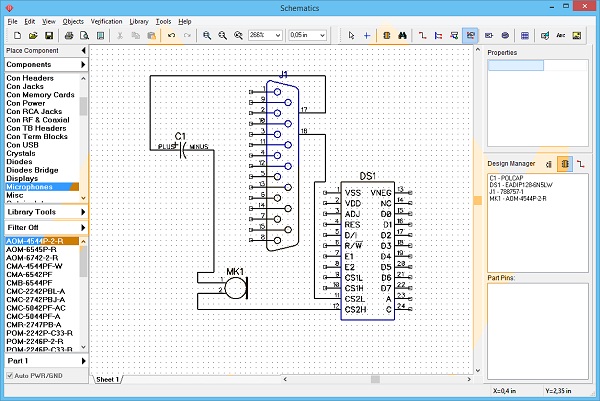

But now that I think about it, it may be completely unwise to hang the driver IC off the microcontroller so I think I should put a dedicated regulator on there. That regulator is providing 5V for the microcontroller and the microcontroller is providing 3.3V to the QFN. It is supposed to be connected to ground and is not. Also, thanks for bringing my attention to it. There are smaller bypassing caps all over the place, the big cap is meant for the power section up top. God knows if this is the right value, it's only a guess. I had to smash it to move the pads around a bit and it lost the label. It's very difficult to communicate this kind of thing via text, and if you're going to put it in some sort of drawing, you might as well just put it in the actual design tool to begin with.There are through holes for a 2200uF/16V electrolytic cap to the right of the barrel jack in the top left. You can probably see why the PCB support wanted this in gerbers now. This way, when you tent the via, the hole will be filled (so you don't wick solder), and you still save space (although not as much) Move the via out of the pad, so that the drilled hole itself does not overlap the SMD pad.Leaving the via exposed, and just add lots of solder to those pads, expecting it to wick into the via.If you must do this kind of thing, there's 2 things I'd recommend: This will make soldering the pad difficult in a best case scenario. The problem here is that if you're putting a via in a pad, you can't just "fill" the via, because the solder resist will impact the normal SMD pad you've merged it with. It's a special process, and usually costs extra (by a lot). This is, confusingly, sometimes referred to as "via in pad", but it's not directly related to simply putting a via in a pad. This is a process where a conductive material is pushed into the via, and then it's given a flat surface, so it more or less acts like a normal SMD pad. "Filled" or "capped" vias are most likely what you're picturing.

"Tented" vias refers to covering vias them with solder resist (the epoxy-like material), making them inaccessible and not exposed. This could be the wrong terminology, depending on your exact expectations here. RF, PLC, CAD, HW Startups, Robotics, Microcomputing, DIY Audio, DIY Gear, DIY, Mindstorms, ASM, EE Books, Product Design, LabVIEW, Breadboard, RTLSDR, Manufacturing, Electronic Circuits.

#Diptrace tented vias how to#

#Diptrace tented vias pro#

Pro ($$$$): Altium, Allegro, OrCAD, PADS, Xpedition. WIKI / FAQ / PCB Review Tips / 3D models / SPICE models / Book ListĮagle, Fritzing, Horizon, KiCad, LibrePCB, ( Comparison).

Links within /r/PrintedCircuitBoard subreddit: Please ask basic electronics questions at /r/AskElectronics This subreddit isn't meant for repairing or modding a PCB. Official Printed Circuit Board Subreddit - review / layout / manufacture / assembly / soldering / schematic capture / simulation.

0 kommentar(er)

0 kommentar(er)